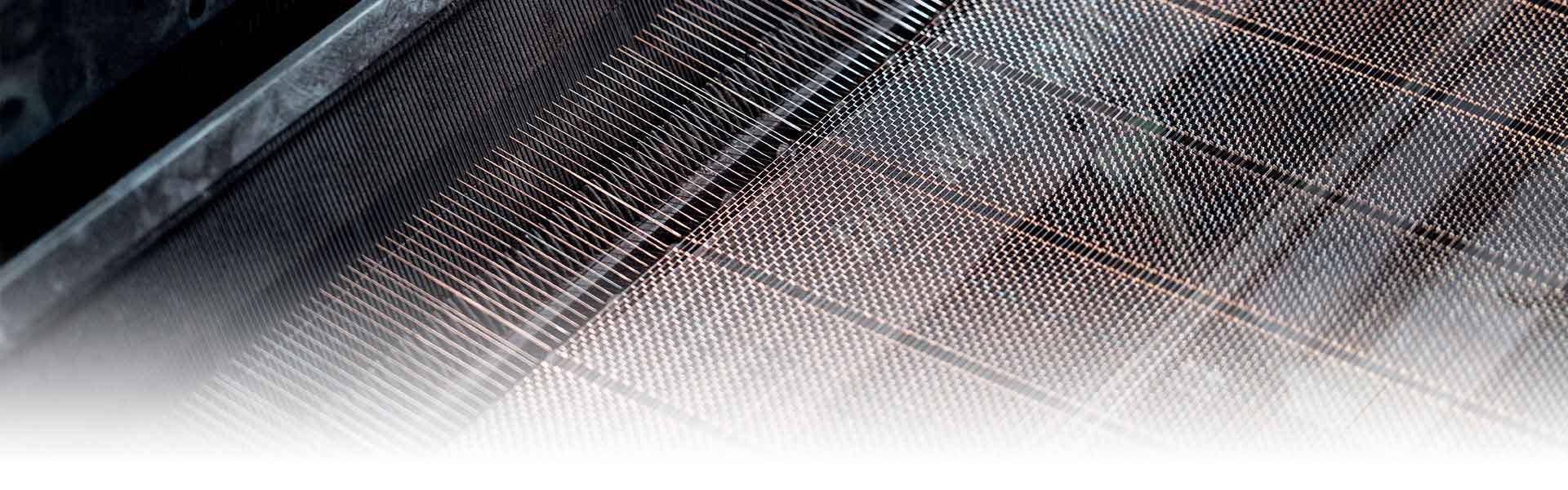

As a manufacturer of woven wire mesh, we offer our own ‘partners in design’ approach to ensure our products are optimized to meet our customers’ product requirements. From certified documentation of our raw materials, consistency and precision in our weaving and post processes, to providing customized kitting and packaging solutions, IWM ensures the best value to our customers. IWM maintains excellence in our product quality through stringent compliance to our ISO 9001:2015 certified quality management systems.

Below, please find general specifications for several of our standard metal meshes which are typically in continuous production. For additional information concerning material specifications, technical processes, and design considerations concerning our woven wire meshes, please see our Technical section concerning materials and mesh specifications. For information concerning our available post fabrication processes please see our Contract Manufacturing section.

We invite you to learn more about IWM capabilities in supporting your woven wire mesh requirements and to see why our customers have continued to rely on our quality products since 1888.

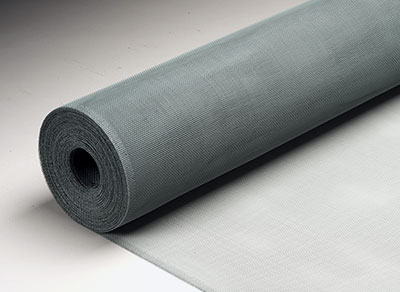

Aluminum Woven Wire Mesh

Applications include: Air & Liquid Filtration Support Media, Composite & Aerostructure Conductive & Structural Media, Communication Antenna Reflective Media

IWM offers a variety of aluminum woven wire meshes in mesh counts starting at 4 x 4 offered as roll goods, cut to size, and die punched or formed parts. IWM produces our standard 5154A Aluminum mesh in roll lengths up to 3000 feet and slit widths as narrow as 1 inch. IWM offers DFARS compliant aluminum woven wire mesh for US government and military applications.

General Specifications & Capabilities

| Alloys | 5154A, Other Alloys Upon Request | Wire Diameters: | 0.005in. – 0.025in. |

| Mesh Range: | 4 - 40 | Available Post Processes: | Annealed, Calendared, Trimmed or Slit to Width, Cut to Size, Die Stamped or Formed |

| Widths: | 1in. to 84in. | Finishes: | Cleaned only, Varnished, Electrodeposition Painting, Epoxy or Polyester Powder Coat |

| Alloys: | 5154A, Other Alloys Upon Request |

| Mesh Range: | 4 - 40 |

| Widths: | 1in. to 84in. |

| Wire Diameters: | 0.005in. – 0.025in. |

| Available Post Processes: | Annealed, Calendared, Trimmed or Slit to Width, Cut to Size, Die Stamped or Formed |

| Finishes: | Cleaned only, Varnished, Electrodeposition Painting, Epoxy or Polyester Powder Coat |

Low Carbon Steel Woven Wire Mesh

Applications include: Air & Liquid Filtration Support Media, Electromagnetic Shielding Media, Screen for Consumer, Fenestration, & Packaging Products

IWM offers a variety of low carbon steel woven wire meshes in mesh counts starting at 4 x 4 offered as roll goods, cut to size, and die punched or formed parts. IWM produces our steel mesh in roll lengths up to 3000 feet and slit widths as narrow as 1 inch. IWM offers galvanized steel mesh which is electrogalvanized in roll form after weaving for enhanced corrosion resistance and increased life cycle.

General Specifications & Capabilities

| Alloys | AISI 1005-1010 Low Carbon | Wire Diameters: | 0.005in. – 0.025in. |

| Mesh Range: | 4 – 40 | Available Post Processes: | Annealed, Electrogalvanized, Calendared, Trimmed or Slit to Width, Cut to Size, Die Stamped or Formed |

| Widths: | 1in. to 84in. | Finishes: | Copper Coated, Cleaned only, Electrodeposition Painting, Epoxy or Polyester Powder Coat |

| Alloys: | AISI 1005-1010 Low Carbon |

| Mesh Range: | 4 - 40 |

| Widths: | 1in. to 84in. |

| Wire Diameters: | 0.005in. – 0.025in. |

| Available Post Processes: | Annealed, Electrogalvanized, Calendared, Trimmed or Slit to Width, Cut to Size, Die Stamped or Formed |

| Finishes: | Copper Coated, Cleaned only, Electrodeposition Painting, Epoxy or Polyester Powder Coat |

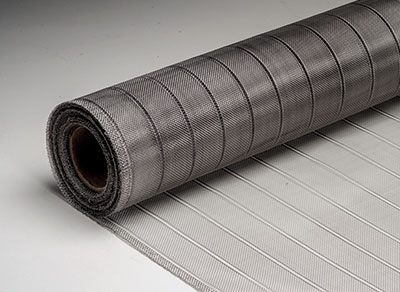

Stainless Steel Woven Wire Mesh

Applications include: Air & Liquid Filtration, Structural & Electro Dissipative Media, Screen for Consumer, Fenestration, & Packaging Products

IWM offers a variety of stainless steel woven wire meshes in mesh counts starting at 2 x 2 offered as roll goods, sheared to size, and die punched or formed parts. IWM’s stainless mesh is offered in standard roll lengths of 100 feet and slit widths as narrow as 1 inch. IWM offers DFARS compliant stainless woven wire mesh for US government and military applications.

General Specifications & Capabilities

| Alloys | UNS S30400, S31600, & 17-7PH | Wire Diameters: | 0.001in. – 0.028in. |

| Mesh Range: | 2 – 325 | Available Post Processes: | Annealed, Calendared, Trimmed or Slit to Width, Sheared to Size, Die Stamped or Formed |

| Widths: | 1in. to 60in. | Finishes: | Cleaned only, Passivated, Electrodeposition Painting, Epoxy or Polyester Powder Coat |

| Alloys: | UNS S30400, S31600, & 17-7PH |

| Mesh Range: | 2 – 325 |

| Widths: | 1in. to 60in. |

| Wire Diameters: | 0.001in. – 0.028in. |

| Available Post Processes: | Annealed, Calendared, Trimmed or Slit to Width, Sheared to Size, Die Stamped or Formed |

| Finishes: | Cleaned only, Passivated, Electrodeposition Painting, Epoxy or Polyester Powder Coat |

Copper Alloys & Commercial Bronze Woven Wire Mesh

Applications include: Conductive Meshes for Grounding or RFI Shielding, Screen for Marine or Corrosive Applications, Malleable Structural Media for Architectural Designs

IWM offers a variety of copper wire meshes in mesh counts starting at 10 x 10 offered as roll goods, cut to size, and die punched or formed parts. IWM typically maintains inventory of C220 (Commercial Bronze) which is part of the brass family of copper alloys which is ideal for use in marine or high corrosive applications.

General Specifications & Capabilities

| Alloys | UNS C100 Copper UNS C200 Brass | Wire Diameters: | 0.009in. – 0.025in. |

| Mesh Range: | 10 - 24 | Available Post Processes: | Annealed, Calendared, Trimmed or Slit to Width, Cut to Size, Die Stamped or Formed |

| Widths: | 1in. to 72in. | Finishes: | Cleaned Only, Varnished |

| Alloys: | UNS C100 Copper UNS C200 Brass |

| Mesh Range: | 10 - 24 |

| Widths: | 1in. to 72in. |

| Wire Diameters: | 0.009in. – 0.025in. |

| Available Post Processes: | Annealed, Calendared, Trimmed or Slit to Width, Cut to Size, Die Stamped or Formed |

| Finishes: | Cleaned Only, Varnished |